Quality Control and Assurance

How do we assure workwear garment quality end to end?

Jon Monsir partners with suppliers that run dedicated QA (Quality Assurance) divisions and enforce rigorous QC (Quality Control) at every stage of workwear uniform production and supply. This includes controlled specifications, in-line checks, pre-dispatch inspections, and documented sign-offs.

Sizing & Fit Consistency

How is sizing accuracy maintained?

Multi-stage inspections: Factory and vendor QCs check from cutting → sewing lines → packing/finishing.

Spec-driven: Every garment is measured against an approved specification sheet covering critical and non-critical measurement points.

Reference samples: Approved gold-seal samples are held onsite to verify styling, construction, and grading before bulk release.

Corrective actions: Any variance triggers re-measurement, correction, and sign-off before shipment.

Colour & Fabric Standards

How do you keep colour consistent between batches?

Pre-bulk approvals: Lab dips are reviewed and approved prior to bulk dyeing.

Shade bands: Vendors submit shade bands for approval, defining acceptable colour tolerance per shipment.

Repeat orders: The same controls apply to every new and repeat production run to minimise drift.

Fabric Performance & Durability

What testing proves fabric durability?

Laboratory validation: Independent testing with Intertek Testing Services (primary lab) and Qualspec Testing Centre (secondary) verifies performance.

Test scope includes: colour fastness to washing, crocking (rub), dry-cleaning solvents, light exposure, water resistance, and ageing.

Pass/fail protocol: Materials that fail are rejected, rectified by the mill, and resubmitted for approval before production proceeds.

Quality Control & Assurance — FAQs

Q: How do you ensure consistent sizing and fit?

A: Multi-stage QC (cutting → sewing → packing), spec-sheet measurements at critical/non-critical points, and onsite gold-seal samples to verify styling and grading.

Q: How is colour kept consistent across shipments?

A: Our suppliers approve lab dips before bulk dyeing and use vendor shade bands to set tolerance limits for every new and repeat run.

Q: Which fabric tests do you run?

A: Independent labs test colour fastness (wash, crock, solvent), light exposure, water resistance, and ageing to validate durability before release.

Q: What if fabric or production fails a test?

A: Non-conforming materials are rejected, corrected by the manufacturer, and resubmitted for approval; shipments only proceed after passing results.

How do we validate fabric and garment quality?

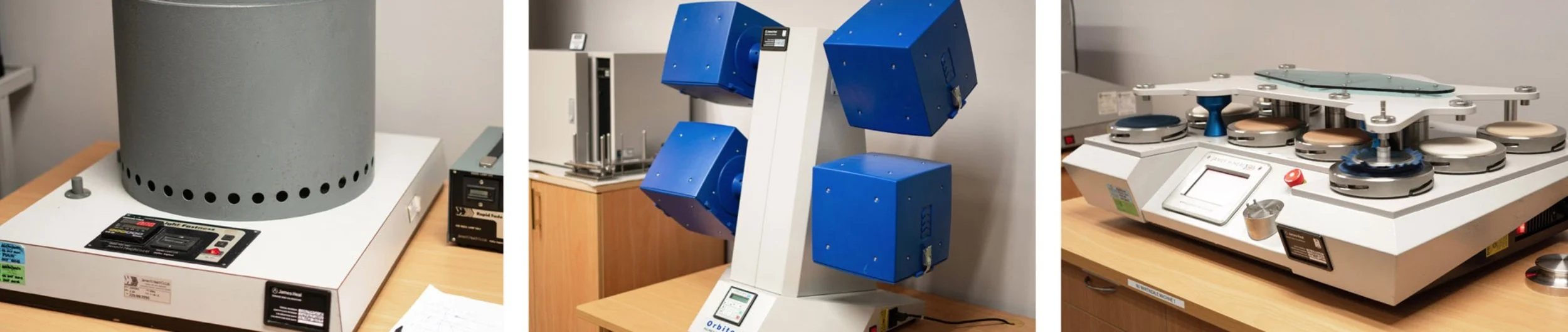

Jon Monsir partners with a supply chain that has invested in dedicated QC (Quality Control) infrastructure, including a laboratory in Auckland equipped with James Heal (UK) testing machinery. This enables continuous, standards-aligned validation of:

Pilling

Abrasion resistance

Light fastness

Rubbing/crocking

Independent test reports are retained for audit. Results inform release decisions, re-tests, or corrective actions before bulk dispatch.

How do vendor standards stay consistent?

Our long-standing vendor network operates to strict specifications and documented QA workflows (in-line checks, pre-dispatch inspections, sample sign-offs). Their local expertise and established regional networks help ensure compliance, reliability, and repeatability across production runs.

Q: Does this governance apply to branding facilities (e.g. embroidery)?

A: Yes. The same quality expectations extend to subcontracted branding partners, with checks prior to dispatch.